Ikhwalithi Ephakeme Yezitolo Ezithengiswayo Ngenani Elincintisanayo Isihlungi Somoya AF25121 AF25122 P785390

Isitolo esidayisa yonke impahlaIkhwalithi ephezulu enenani Elincintisanayo Isihlungi Somoya AF25121 AF25122 P785390

Imininingwane Esheshayo

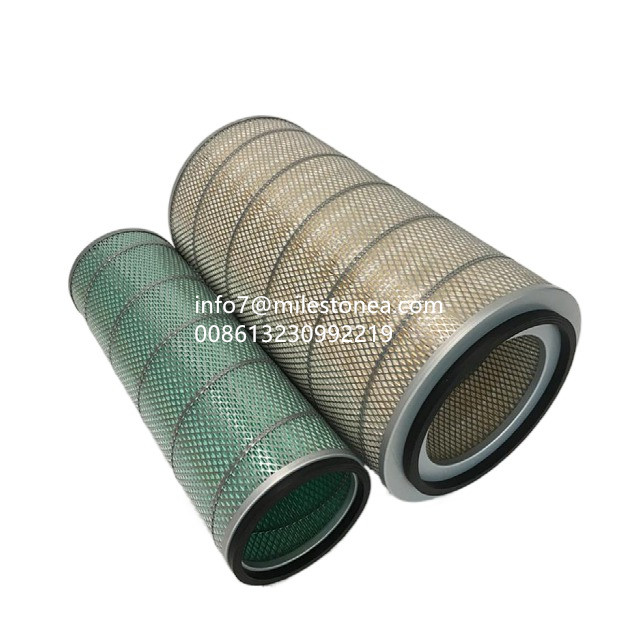

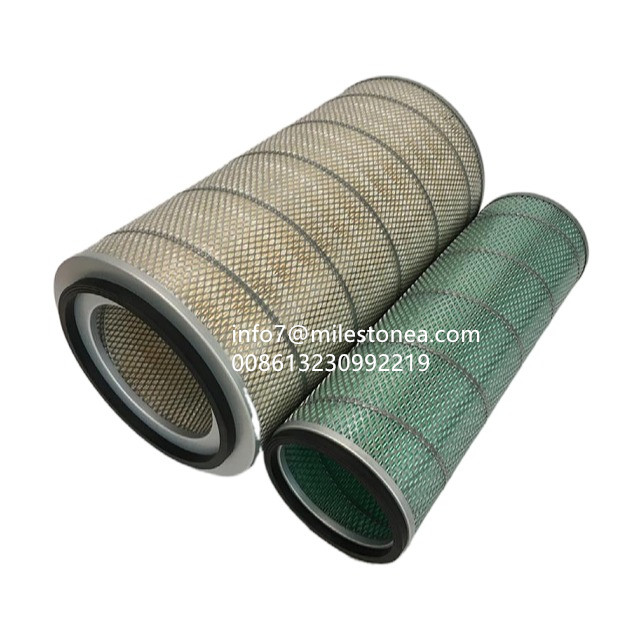

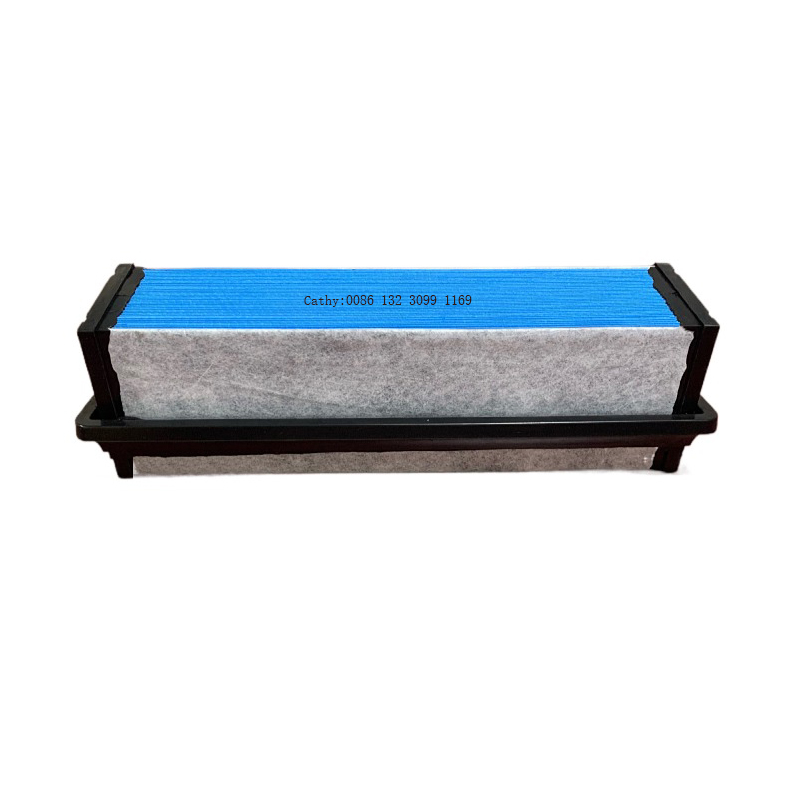

Uhlobo:Isihlungi somoya se-OEM NO:AF25121 AF25122Ubude Sebonke 1:526 mm (20.709 iyintshi) Enkulu OD 1:283 mm (11.142 iyintshi) I-ID Enkulu 1:150.38 mm (5.92 iyintshi) Okubalulekile:Iphepha Lokuhlunga + PU Ubude Babo bonke 2:461 mm (18.15 OD Enkulu kakhulu) OD Enkulu Kakhulu 141.77 mm (5.581 intshi) I-ID Enkulu 2:105.6 mm (4.157 intshi) MOQ:24 Imisa Unyaka:Imodeli Yamazwe Ngamazwe:Ukufaneleka Kwemoto Yonke:Injini Yomhlaba Wonke:Indawo Evela Kuyo Yonke:CN;HUB OE NO.:P785390X770691 OE NO.:P785390I-OE NO.:X770691 OE NO.:AF25121 OE NO.:AF25122 OE NO.:AF25121 AF25122 Usayizi:Isiqinisekiso Esijwayelekile:1 Imodeli Yemoto Yonyaka:Ugandaganda, Iloli, njll.

Umqondo ojwayelekile wengxenye ngayinye yesici sokuhlunga

Zonke izihlungi ezokuvikela izingxenye zenjini, zihlanzekile, zinwebe impilo yesevisi yenjini, ukusuka ebusweni bezihlungi ezahlukahlukene kanye nobude besikhathi esisetshenziswa isihlungi, akulungile ukwahlulela ukuthi isihlungi sihle noma sibi, futhi isihlungi sangempela siyahlulelwa.Ukuthi ikhwalithi yinhle noma yimbi, kufanele siqale sicabangele lezi zici ezilandelayo:

1. Ikhwalithi yephepha lokuhlunga

Iphepha lokuhlunga lekhwalithi enhle kanye nephepha lokuhlunga lekhwalithi ephansi kuyafana phezulu.Kuphela lapho zihlolwa yimishini yokuhlola yefekthri yochwepheshe, kungaba khona umehluko osobala.Izinga lephepha lokuhlunga lihlobene nokusebenza kahle kwesihlungi.Kukhona ukungcola okwengeziwe, insimbi, nothuli ohlelweni.Iphepha lesihlungi elisezingeni eliphansi lihlunga ukungcola okuncane, insimbi, nothuli, elingakwazi ukuvikela injini, futhi izingxenye ezihlobene zenjini kulula ukuzisebenzisa.

2. Ukusebenza kahle kokuhlunga kwesihlungi

Ngokuyinhloko kunqunywa izinga lephepha lokuhlunga elisetshenziswe kusihlungi.Ukusebenza kahle kokuhlunga kwesihlungi kungaphezu kuka-96% okumele kuthathwe njengomkhiqizo oqeqeshiwe.Ngesikhathi injini iqala futhi ishayela, umuzwa womshayeli wenjini nezinga lentuthu yegesi yokukhipha umoya wemoto kuhluke kakhulu lapho injini ilungiswa futhi kubonakala ukuguga kwezingxenye.

3. Izinto ezinamathelayo zephepha lokuhlunga kanye nesivalo sokuphela

Ngephepha lokuhlunga lekhwalithi elihle, kufanele futhi kube nokunamathela okuhle kwekhwalithi.Uma ukukhethwa kungalungile, iphepha lokuhlunga kusihlungi ngeke liboshwe ngokuqinile kuma-caps wokugcina angaphezulu naphansi.Ngesikhathi sokusetshenziswa, amafutha azowa kalula futhi anganamatheli, okuholela kumjikelezo omfushane, akukho mphumela wokuhlunga.

4. Isiqinisekiso senqubo yokukhiqiza

Kusukela phezulu, iphepha lokuhlunga alikwazi ukunamathela ephepheni lokuhlunga, futhi ukuhanjiswa kokukhanya kufanele kubonakale ngaphansi kokukhanya.Uma kungekho ukuhanjiswa kokukhanya ngaphansi kokukhanya, ukunamathela phakathi kwamaphepha okuhlunga kuzothinta ukuhamba kwawo wonkeisihlungi somoyaikhekhe, futhi ukuphila kufushane, okubangela amandla anganele nobuthakathaka, futhi kunzima ukususa uthuli ngesikhathi sokuhlanza.Kuhleisihlungi somoyaayinamatheli phakathi kwamaphepha okuhlunga, inokudlulisa ukukhanya okuqinile, ifanele izindinganiso zokungenisa umoya wenjini, inempilo ende yesevisi, futhi kulula ukuyihlanza.

5. Inqubo yesihlungi somoya

Ukukhetha izinto ezisezingeni eliphezulu zokukhiqiza izihlungi, inqubo yokukhiqiza iyisisekelo sokuqinisekisa ikhwalithi yemikhiqizo.Ziningi izixhumanisi zokukhiqiza zesihlungi.Indlela yokuqinisekisa ukuthi isihlungi singavikela futhi sihlanze ngesikhathi sokusetshenziswa, kanye nokuqinisekisa ukugeleza nokuqinisekisa ukusebenza okuvamile kwenjini, kudinga isiqinisekiso senqubo yesixhumanisi ngasinye senqubo yokukhiqiza.