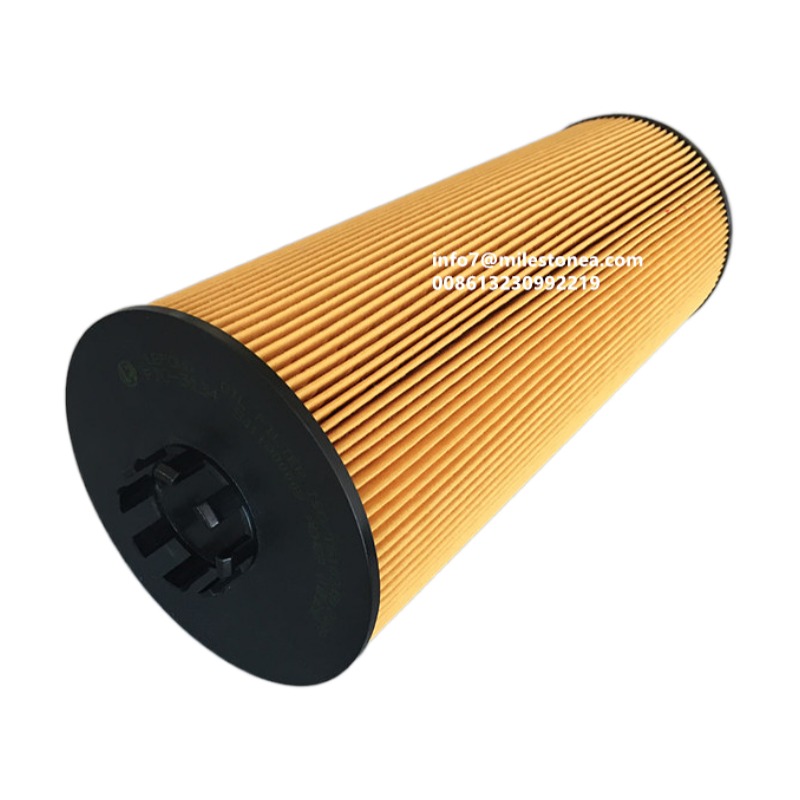

Izihlungi ze-Factory Spin-on-on 1012N-010 LF3349 zengxenye Yenjini

Izihlungi ze-Factory Spin-on Oil I-1012N-010 LF3349 Yengxenye Yenjini

Amamodeli asebenzayo: Cummins

Injini esebenzayo: K50

Imodeli yemishini esebenzayo: P126T1

Ayikho i-valve yesheke Ayikho i-valve yokudlula

Umqondo ojwayelekile wezihlungi ezinhle nezimbi

Zonke izihlungi zivikela izingxenye zenjini, zihlanze futhi zelule impilo yesevisi yenjini.Kusukela ebusweni bezihlungi ezihlukahlukene kanye nobude bokusetshenziswa kwezihlungi, akulungile ukucacisa ikhwalithi yezihlungi.Ikhwalithi yedivayisi kufanele icatshangelwe kuqala kulezi zici ezilandelayo:

1. Ikhwalithi yephepha lokuhlunga

Iphepha lokuhlunga lekhwalithi elihle kanye nephepha lokuhlunga elisezingeni eliphansi kuyafana ukusuka phezulu.Kuphela ngokuhlola ngaphansi kwemishini yokuhlola yefekthri yochwepheshe, kungaba khona umehluko osobala.Izinga lephepha lokuhlunga lihlobene nokusebenza kahle kwesihlungi.Kukhona ukungcola okwengeziwe, insimbi nothuli ohlelweni, kanye nephepha lokuhlunga lezihlungi ezingcolile zekhwalithi, insimbi nothuli.

2. Ukusebenza kahle kokuhlunga kwesihlungi

Ngokuyinhloko kunqunywa izinga lephepha lokuhlunga elisetshenziswe kusihlungi.Ukusebenza kahle kokuhlunga kwesihlungi kungaphezu kuka-96% okumele kuthathwe njengomkhiqizo oqeqeshiwe.Ngesikhathi esifanayo futhi endaweni efanayo, ukusetshenziswa kwezihlungi ezivela kubakhiqizi abahlukene kuhlukile.Umehluko osobala uthi Uma injini iqalwa, ngesikhathi sokushayela, umuzwa womshayeli wenjini kanye nezinga lentuthu yegesi ekhipha umoya wemoto kuhluke kakhulu uma injini ilungiswa futhi izingxenye sezigugile.

3. Iphepha lokuhlunga kanye nempahla yokubopha isiphetho

Ngephepha lokuhlunga lekhwalithi elihle, kukhona nokunamathela okuhle kwekhwalithi.Uma ukukhethwa kungalungile, iphepha lokuhlunga kusihlungi ngeke liboshwe ngokuqinile kuma-caps wokugcina angaphezulu naphansi.Uma uwoyela uhlangana nawo ngesikhathi sokusetshenziswa, kulula ukuwa futhi awunakho ukunamathela.Ibangela ukujikeleza okufushane futhi ayikwazi ukuhlunga.

4. Isiqinisekiso senqubo yokukhiqiza.

Kusukela phezulu, iphepha lokuhlunga kanye nephepha lokuhlunga alikwazi ukunamathela ndawonye.Ukudlulisa kumele kubonakale ekukhanyeni.Uma kungekho ukuhanjiswa kokukhanya ngaphansi kokukhanya, ukunamathela kwephepha lokuhlunga kuzothinta ukuhamba kwesihlungi sonke, ukuphila kufushane, okubangela amandla anganele, ngokomzimba, futhi kunzima ukususa uthuli phakathi nenqubo yokuhlanza.Isihlungi esihle asinamatheli phakathi kwamaphepha okuhlunga, sinokudluliswa kokukhanya okuqinile, silungele izinga lakamuva lenjini, sinempilo ende yesevisi, futhi kulula ukusihlanza.

5. Inqubo yesihlungi

Ukukhetha izinto ezisezingeni eliphezulu zokukhiqiza izihlungi, inqubo yokukhiqiza iyisisekelo sokuqinisekisa ikhwalithi yemikhiqizo.Ziningi izixhumanisi zokukhiqiza zesihlungi.Indlela yokuqinisekisa ukuthi isihlungi singavikela futhi sihlanze ngesikhathi sokusetshenziswa, futhi singaqinisekisa ukugeleza nokuqinisekisa ukusebenza okuvamile kwenjini, kudinga isiqinisekiso senqubo yesixhumanisi ngasinye senqubo yokukhiqiza.

Xhumana nathi

_副本1.jpg)